By Sarah Alexander

Managing Director | Bespoke Safety Group

In previous articles we introduced 4 simple steps to build sustainable workplace health and safety (WHS) processes at your nursery.

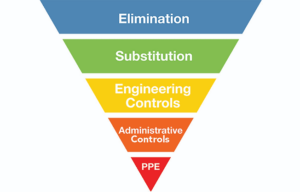

Developing controls starts by deciding which ones have the most impact on reducing risk. In WHS this is called the ‘hierarchy of control’.

The hierarchy of control has five levels; it is a framework for managing hazards in a structured order. It ensures controls are developed in the most effective and reliable way and reduces reliance on human behaviour. Controls chosen at higher levels of the hierarchy typically achieve greater risk reduction and require less continual monitoring and supervision.

1. Elimination

Remove the hazard entirely from the workplace. Eliminating the hazard is the most effective control and must always be considered first.

2. Substitution

Replace the hazard with a safer alternative. For example, use a non-toxic soil treatment instead of a toxic pesticide; or use lighter-weight containers to reduce manual handling risks.

3. Engineering Controls

Physically separate people from hazards or redesign equipment or processes. Engineering controls are reliable because they rely less on individual behaviour. For example, fixed machine guards on equipment, use of mechanical lifting aids, and isolation of noisy equipment.

4. Administrative Controls

Administrative controls change how work is performed through rules, procedures, training, rostering, supervision and signage. They do not remove the hazard and rely on human behaviour and supervision to be effective.

It is very common to see lots of administrative controls in use because they are generally low cost and faster to implement.

Here’s how to overcome common pitfalls when using administrative controls in your workplace:

5. Personal protective equipment (PPE)

PPE is the last line of defence because it relies heavily on correct, consistent human behaviour. PPE leaves the hazard in the workplace and only provides a barrier between the hazard and the worker. Workers must be trained in the correct selection and use of PPE.

Key takeaways:

Read more news and insights from Nursery & Garden Industry Queensland